Welcome to the glittering universe of cold foil printing, where your print projects get a dazzling makeover! Think metallic bling without the cha-ching – that’s cold foil for you. This innovative technique utilizes UV-curable adhesive and ultra-thin metallic films, allowing for stunning, high-resolution designs that traditionally required more expensive methods such as hot stamping.

What is Cold Foil Printing?

Cold foil printing offers a modern twist on metallic effects, using a cold application process instead of traditional hot stamping’s heat and pressure. This method involves applying a UV-curable adhesive to the substrate, followed by a metallic foil that adheres only where the adhesive is applied. It allows for finer details and a broader range of colors over traditional methods, making it suitable for high-quality print materials needed across various industries.

How Cold Foil Works

The cold foil process begins with the application of a UV-curable adhesive printed onto the substrate using conventional printing plates. Unlike hot foil stamping which requires heat, cold foil leverages UV light to activate and set the adhesive. Here’s a step-by-step breakdown:

- Adhesive Application: The process begins with the application of a UV-curable adhesive printed onto the substrate using conventional printing plates.

- Foil Application: A thin metallic foil is pressed onto the adhesive-coated areas.

- Curing Process: The substrate with adhesive and foil passes under UV lights, curing the adhesive and bonding the foil permanently.

- Excess Removal: The polyester liner and any excess foil not adhered are removed, leaving a clean and precise metallic finish on designated areas.

- Final Output: The result is a vibrant metallic finish with exact detailing.

Materials Used in Cold Foil Printing

The materials involved in cold foil printing are pivotal in achieving its unique metallic effects. At the heart of this process is the metallic foil, usually composed of a thin layer of metal deposited on a film, typically made from polyester. This polyester carrier plays a crucial role as it ensures a seamless transfer of the metallic foil to the substrate during the printing process.

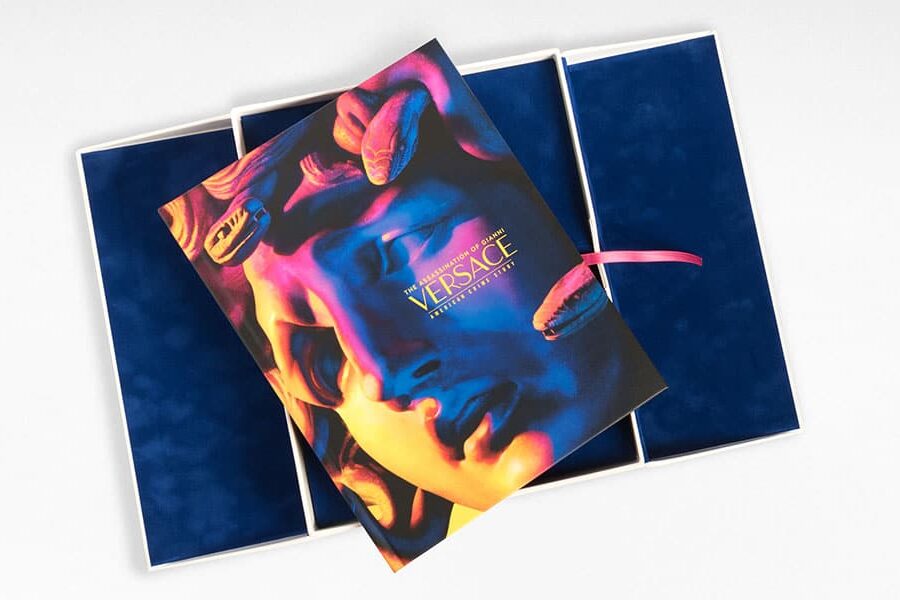

Variety of Foils: While silver and gold are the standard choices due to their traditional metallic look, cold foil printing is not limited to these options. The technology also allows for the use of a variety of metallic colors and holographic materials. These can produce dazzling visual effects ranging from subtle glimmers to vibrant reflections.

Customization and Effects: The diversity in foil materials enables printers to tailor effects according to specific project requirements. For example, holographic foils can create a three-dimensional illusion, adding depth and movement to prints, making them more engaging and eye-catching.

Key Benefits of Cold Foil Printing

Cold foil printing offers numerous advantages that make it an attractive option for various printing projects:

- Overprinting Capability: Overprinting on cold foil allows for additional color layers on the foil, creating complex visual textures and rich color dynamics that are not possible with traditional foil stamping.

- Cost Efficiency: Economical for large print runs, avoiding expensive metal dies.

- High Detail and Versatility: Capable of producing intricate designs with the possibility of overprinting in multiple colors.

- Quick Production Times: Enhancements are applied in a single pass during the regular printing cycle.

- Environmental Benefits: Less energy-intensive than hot stamping and utilizes recyclable materials.

DVC – Your Cold Foil Print Experts

Cold foil printing revolutionizes traditional printing with its efficiency, cost-effectiveness, and stunning visual outcomes. Stay tuned for “Cold Foil Chronicles: Part 2 – The Magic of Overprinting” where we will explore advanced cold foil techniques.