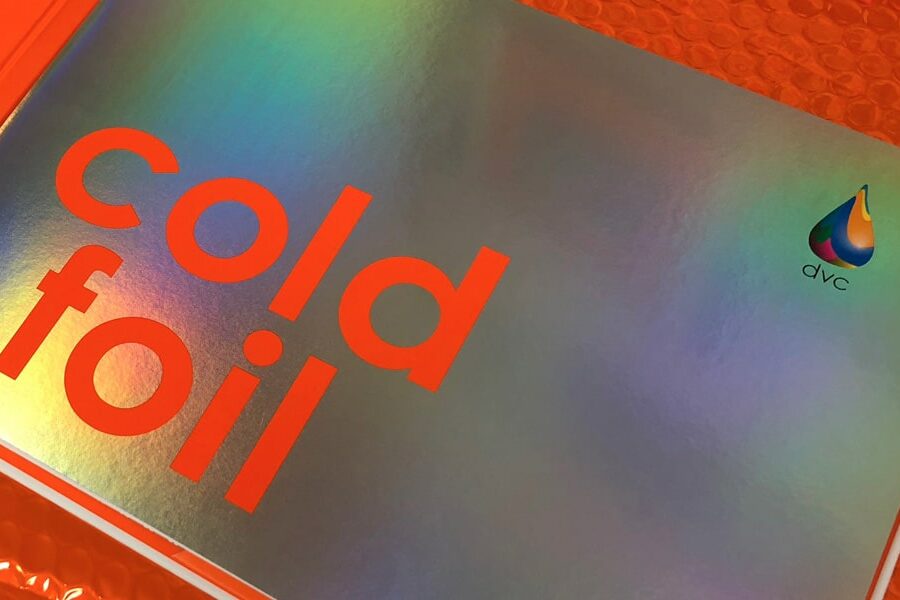

Welcome back to the dazzling world of cold foil printing! In Part 1, we explored the fundamentals of cold foil printing, how it added a touch of metallic brilliance to your print projects without the added step and cost of traditional hot stamping. Now, in Part 2, we’re about to uncover the power of overprinting on cold foil, a technique that can elevate your designs to new heights.

To fully leverage cold foil, understanding overprinting is essential, as printing colors over a metallic base allows designers to achieve vibrant color dynamics, opening up endless creative possibilities.

How Overprinting Works

Diving into the mechanics of overprinting reveals its true sophistication. We’ll examine how each step in the process contributes to the final piece. Overprinting on cold foil involves a precise and controlled layering process:

- Initial Foil Application: A metallic foil is applied to designated areas of the substrate using UV-curable adhesive.

- Printing: Once the foil adheres to the substrate, additional color layers are printed over the foil using conventional printing methods.

- Final Touches: The result is a vibrant, multi-layered design with enhanced visual appeal.

The ability to print colors over metallic foil allows designers to expand the gamut of metallic colors to create richer and more visually appealing prints.

Design Possibilities and Creative Applications

The world of design is filled with limitless opportunities, and overprinting on cold foil expands these horizons even further. Here, we explore some of the innovative ways designers can utilize this technique. Overprinting on cold foil opens up a realm of creative possibilities:

- Enhanced Color Vibrancy: The metallic base amplifies the brightness of overlaid colors, resulting in eye-catching visuals.

- Added Depth and Texture: The layering process creates an illusion of texture and depth, making designs more engaging.

- Dynamic Visual Effects: By experimenting with various color combinations and foil types, designers can achieve unique effects that capture attention and convey a sense of luxury.

For example, consider a high-end perfume packaging that uses overprinting to create intricate floral patterns with shimmering accents, elevating the product’s perceived value.

Advantages of Overprinting on Cold Foil

Understanding the benefits of overprinting can transform how brands approach their design strategies. The key advantages that make this technique is an industry game-changer. The benefits of overprinting on cold foil are numerous and impactful:

- Enhanced Brand Appeal: Designs with overprinted cold foil stand out on shelves, attracting consumers and reinforcing brand identity.

- Cost-Effective: While offering premium visual effects, the process remains economical, especially for large print runs.

- Versatile Applications: From luxury packaging to business cards, the technique is adaptable across various industries and projects.

Want to give your printing a shiny upgrade with cold foil technology?

The art of overprinting on cold foil transforms ordinary designs into extraordinary visual experiences. This technique adds a touch of magic to any print project while conveying premium quality. Reach out to DVC and let’s make your brand stand out like a diamond in a sea of paper!

Stay tuned for the next installment, “Cold Foil Chronicles: Part 3 – Debunking the Myths,” where we’ll bust some rumors. Don’t miss it!